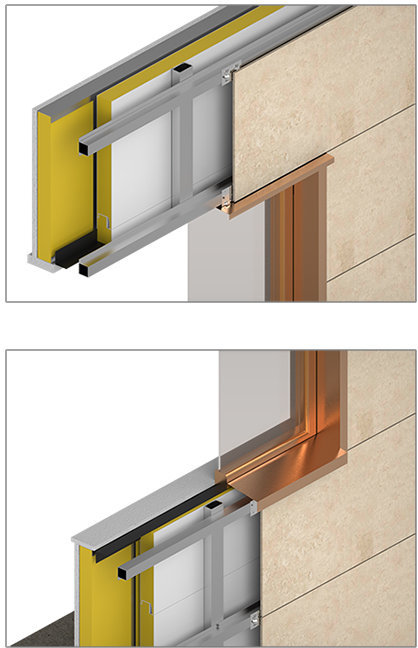

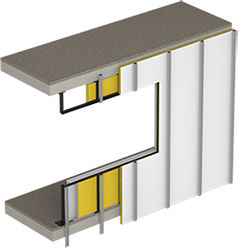

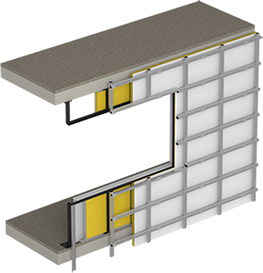

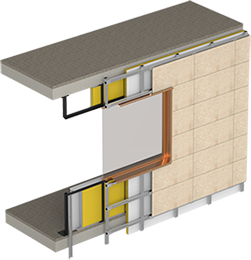

Sistema de cerramiento integral construido en seco a base de panel sandwich combinado con fachada ventilada. Está basado en un proceso constructivo secuencial, en el que se van montando diferentes capas, dependientes unas de otras, que funcionan como un todo. Es totalmente desmontable y recuperable, lo que aumenta su versatilidad.

Dentro de los sistemas secos, el sistema DRY INVERT se caracteriza por: